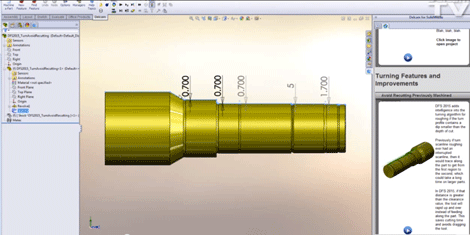

Ultimately, this technology can be transformative because it allows manufacturers to automate the design-to-manufacturing process fully. It also aids experienced users by allowing them to program much faster. It allows novice CAM users to get up to speed quickly by automating the tedious and repetitive tasks associated with most mainstream CAM software. In essence, rules-based Machining is like having a built-in manufacturing consultant help make team decisions. These rules are included out of the box and can be easily modified while the CAM user is programming by simply changing the parameters and clicking save. Proven machining strategies, or rules, embedded into the software, allow for faster toolpath creation-in many cases, five to ten times faster. Other benefits include a better understanding of manufacturing processes during the design phase and a faster development cycle, which manufacturers of every size need.Īs these advantages become clearer, the critical question changes from “Could my design and engineering teams fill the gap?” to “What tools will allow me to do this?”Ī New Way to Automate With “Rules-Based” Machining

The first advantage is bringing critical manufacturing in-house, which will help control quality and reduce manufacturing costs exponentially. This thinking leads to new possibilities with clear advantages for workflow. After all, if there was a way to capture lost expert knowledge, your team could easily compensate for the lack of know-how by automating and standardizing processes. While this sounds like an ‘‘easier said than done’’ scenario, it’s not impossible. When looking to replace the loss in CAM expertise, what if you used your existing design and engineering teams (who have little or no CAM training) to help fill the gap rather than adding more people to your team? You might not know that a smarter solution to the experience problem exists. You’ll also be aware that a lack of experience costs time and money in both your design and manufacturing processes. It’s causing a widening skills gap, but if you’re a shop owner or manager, you probably already know this. The current workforce is aging out, and a lack of new trained talent is draining today’s manufacturers of reliable CNC programmers and their expert knowledge of manufacturing techniques. Ask manufacturers about the biggest challenge facing their industry most will mention a shrinking pool of experienced talent near the top.

0 kommentar(er)

0 kommentar(er)